SILICONEAT THE SERVICE OF INDUSTRY

SILICONEAT THE SERVICE OF INDUSTRY

Industry

Our industries, more and more modern, require products which should be always more efficient. In this case, products have to meet different criteria regarding productivity and durability while remaining reliable. Thanks to silicone, those kinds of performance become possible for hundred of applications...

At STERNE

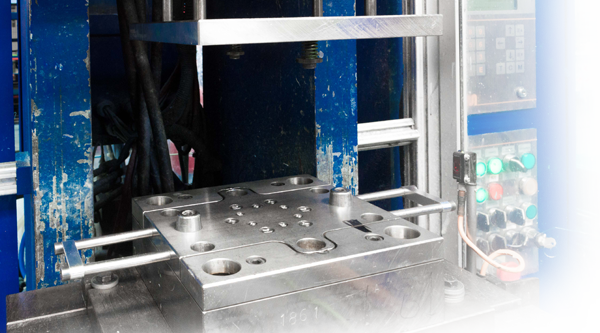

We have working environments dedicated to manufacturing specific parts for all industries. Our production workshops are located in a 2500m² factory that is divided into complementary areas of activity : molding, extrusion, making and finishing allow us to propose a ready to use product.

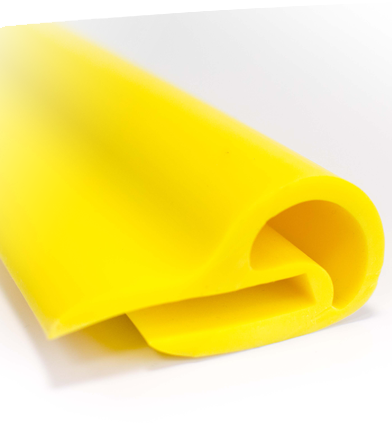

We have a large choice of solid and liquid rubber silicone, with hardness from 1 to 90 shore A+/-5, in a large choice of colors, approval possibilities according to specifications

Depending of your needs, we also have a large choice of sponge silicone (cellular silicone) with density and colors according to specifications, with specific quality levels ; as well as other rubbers and elastomers as VITON®, EPDM, Nitrile, FKM, FPM, Neoprene...

To ensure quality service and product traceability, we have set up a quality management system according to ISO 9001:2015 and ISO 13485:2016 standards.

Silicone material, our expertise and our know-how allow us to meet various needs of different industries. As such, our R&D and laboratory teams follow-up on your development so that our products meet with your specific technical characteristics.

Here are some examples of applications developed for different industries :

• Inflatable seals for nuclear, chemistry and boiler fields

• Gaskets for military, maintenance, packing, cleaning , and sanitary fields

• Gaskets, fluid and powder transfers for various industries such as lighting and stokehole: air conditioning, water heater, boilers,...