EXPERT IN SILICONESINCE 1996

EXPERT IN SILICONESINCE 1996

Silicone raw material

Download our white paper

Silicone elastomer is a thermosetting material that is processed from compact silicone rubber and liquid resin. Its transformation is very similar to plastic. Crosslinking/curing, in opposition to plastics, occurs when silicone is in contact with a temperature source such as infrared, electrical resistance and hot air, or moisture.

Experts in silicone elastomers since 1996, the company Sterne uses, at this stage, several kinds of silicone elastomers, with different consistencies :

resin, mastic, High Consistency Silicone Rubber (HCR) and Liquid Silicone Rubber (LSR) with two main catalysts : peroxide and platinum.

With an emphasis on innovation, and the desire to meet specific needs in various markets, the Sterne Company has developed, within its laboratory, materials having specific technical characteristics and properties.

With an emphasis on innovation, and the desire to meet specific needs in various markets, the Sterne Company has developed, within its laboratory, materials having specific technical characteristics and properties.

Our brands

SWELLSIL™ Sponge silicone which can be FDA &/or resist to 300°C (extrusion)

STIRLENE™ Silicone rubber with high temperature properties, it withstands up to 400°C heat, and is conceived for extreme uses

ELASTALERN™ Fluoro carbon with elastic properties

STIRMOTIV™ Homologated silicone rubber specifically for the railway industry

STAMINALENE™ High fatigability resistance platinum-cured silicone

DIODON™ Inflatable Silicone seals technology and specific testing

HIGHTUBE™ Peroxide silicone rubber for peristaltic pumps applications

Why choose an LSR (Liquid Silcone Rubber)

rather than a HCR (High Consistency Rubber Silicone)?

LSR :

• LSR is a polymer composed of short chains, thus viscosity will be low, with a texture similar to honey. It allows rapid processing.

• Hardness between 5 and 75 Shore A, Post Cured and Non Post Cured (with a good physical balance between 40 and 65 Shore A)

• LSR is ideal for the production of sensitive items: silicone items with complex geometry, thin and small parts

• It allows mass production, but requires specific equipment

• No human manipulation of the material is required, avoiding impurities

• Mainly used for injection molding

HCR :

• HCR is a polymer composed of medium chains that does not allow quick processing.

• Hardness is situated between 15 and 90 Shore A, Post Cured and Non Post Cured.

• Used mainly for the design/production of silicone items with an important volumic mass.

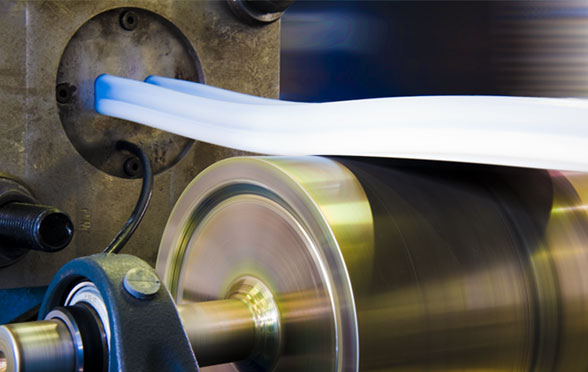

• Can be used with all types of production technology: compression and injection molding, extrusion, calendaring for unique parts, and small to medium series.

• Great flexibility of composition.