TOWARDS NEW METHODS

TOWARDS NEW METHODS

UV

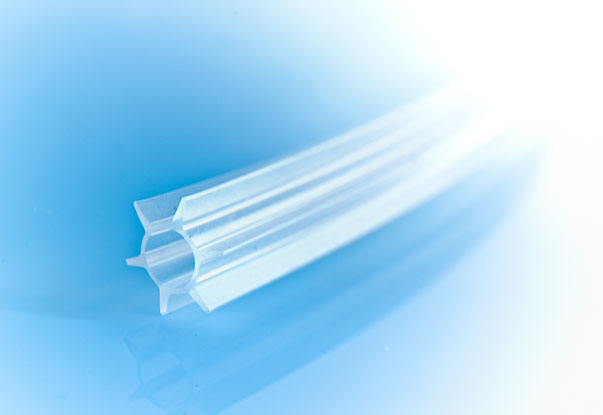

With our knowledge of the constraints of silicone materials, we have done the research to overcome them to develop new manufacturing processes, in particular with the use of UV, so that we can bypass these constraints and meet your needs.

It is at the heart of Sterne that our technical and laboratory teams have developed manufacturing processes completely dedicated to UV production. Extrusion, molding and additive manufacturing by UV curing are now an integral part of the Sterne’s expertise.

It is in 2015, that the first drafts were created. Working closely with the Momentive Company, specialized in materials development, we have implemented manufacturing processes that allow silicone UV curing. Unlike conventional heat-cured silicones, silicones developed by Momentive are UV-cured while at the same time preserving all their technical properties.

The advantages UV silicones

• A shorter curing reaction that requires less energy

• Cold-curing (<70°C) thanks to UV, thus allowing the combination with thermosensitive materials (plastic, electronics, etc.)

• A sustainable development approach: UV rays consume less energy than conventional oven curing or heating machines (hot air, radiant, cartridges, etc.).

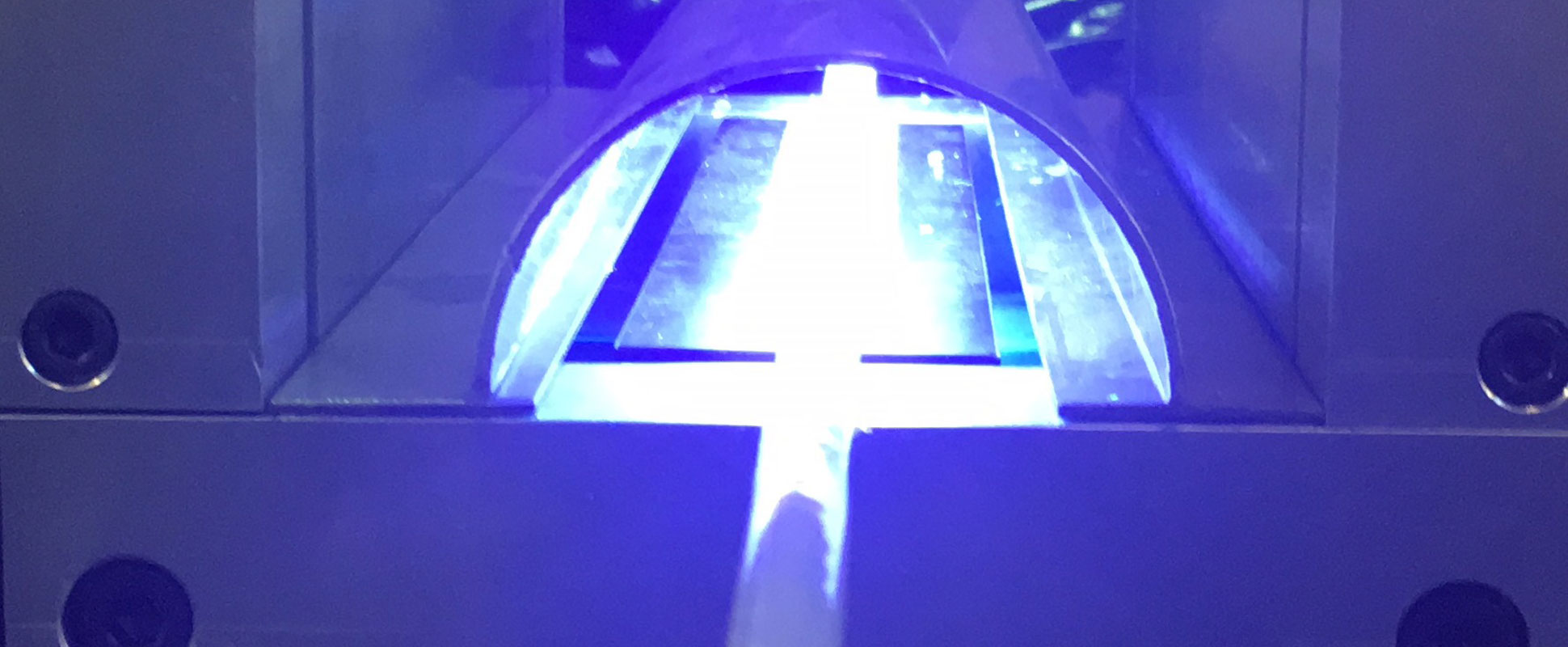

An environment dedicated to UV manufacturing processes

It is after evaluating the strategic issues and the range of new technical solutions possible using UV silicones that Sterne has decided to allocate a specific budget to the research & development of UV processes.

In addition to production tools such as molding machines and extruders that can be used for UV, Sterne has dedicated a workplace nearly 100m2 to this type of special treatment production.